The Most Complete Differences Between Emboss and Deboss

What is the difference between Emboss and Deboss? We often find this service in various products such as packaging, wallets, and various other types of products that have a concave or embossed shape. So, what are the prominent differences between these two types of print finishing? Scroll down to find out the full explanation.

Differences between Emboss and Deboss

Both types of print finishing have the same concept, namely by pressing the paper to get an additional effect of better print finishing results.

To decide which finishing service you will choose, let's check the differences between Emboss and Deboss, here:

Understanding Deboss and Emboss

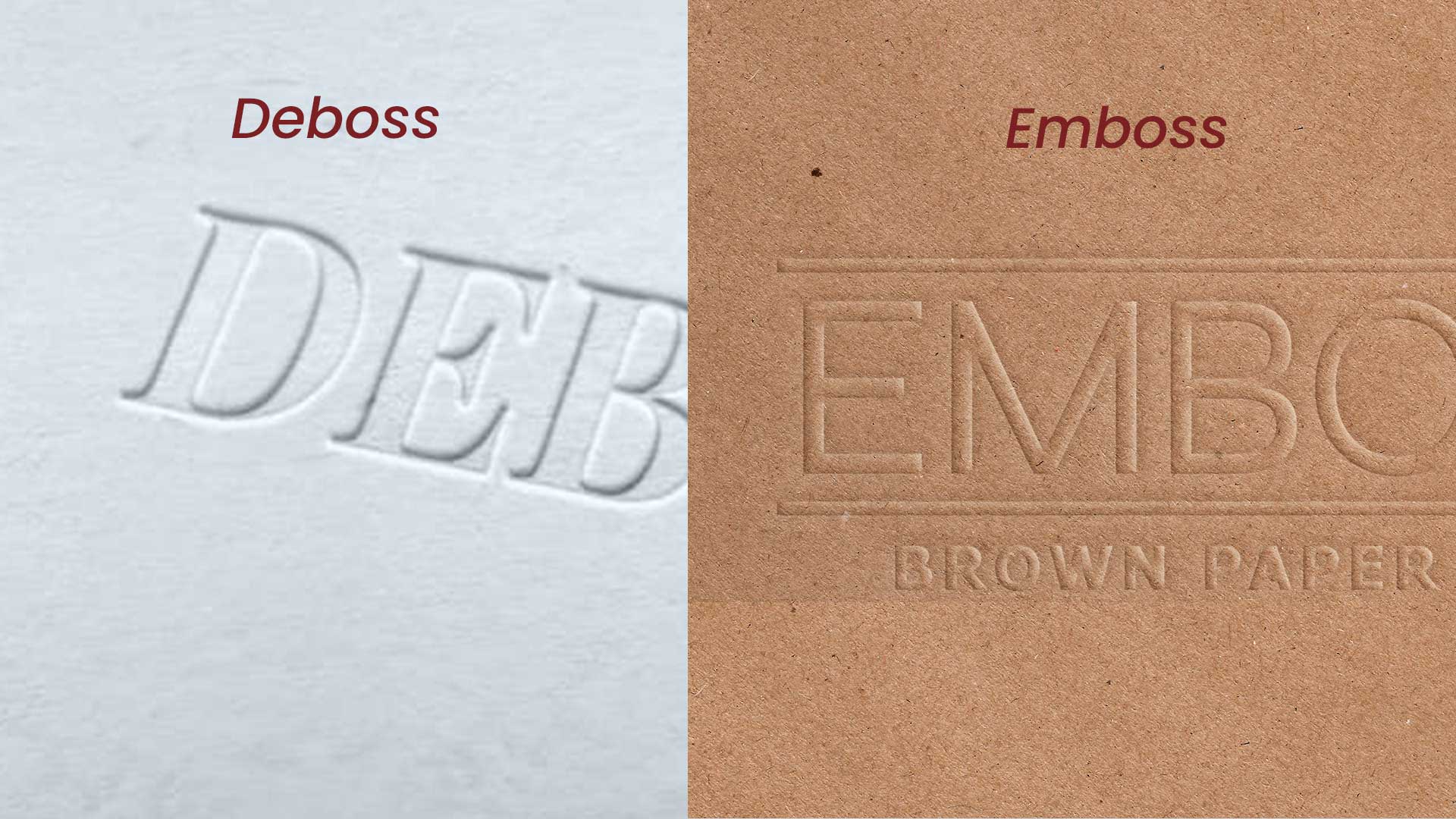

Deboss is a print finishing technique that makes the surface of the print embossed. The embossed part will rise to the surface according to the design applied to provide a more attractive 3D effect. This technique is often applied to highlight certain logos or design elements, which can give a luxurious impression.

Meanwhile, Deboss itself is the opposite of Emboss, where the printed part will be pressed inward, so that the surface of the material will appear to sink inward. The resulting effect can create an elegant texture. This technique is often used in books, invitations, or products with minimalist designs.

The Prominent Differences Between Deboss and Emboss

Deboss and Emboss have similar end results, both can change the design to be more elegant, besides that there are prominent differences between these two types of print finishing, my finishing friends.

Embossing is a 3D final result that is made to protrude into the embossing using less heat when compared to debossing.

The Embossing technique uses 2 molds, while Debossing only requires 1 mold.

Emboss vs Deboss, Which is More Expensive

As Admin has explained previously, Embossing uses 2 molds while Debossing uses only 1 mold, meaning that the Embossing technique is more expensive than Debossing.

Best Emboss and Deboss Service in Surabaya

Pelangi UV is the best Emboss and Deboss printing finishing service with sophisticated and updated machines. There are 2 types of Emboss and Deboss finishing machines consisting of automatic and manual machines with a capacity of 60,000 prints / day. For a minimum order, Finishing Friends can order a minimum service of Rp. 120,000.

Consult and order Emboss and Deboss services, you can contact Whatsapp: 0822 3101 9363